Admiralty Pattern Cones

Small cone-shaped drag devices have been around since the early 1800's. These had to be used in conjunction with a riding sail and had a reputation for putting great strains on sailboat rudders. Joshua Slocum used one on board Spray. John Claus Voss popularized such a device in his Venturesome Voyages (see File S/M-1).

The term sea anchor itself appears about three dozen times in the third edition of Coles's Heavy Weather Sailing, in almost every instance of attempted use the results being dismal. Closer examination, however, will show that in each and every instance the term is misapplied to a small admiralty pattern cone, probably about 21 inches in diameter (see pages 98, 102, third edition).

A 21-inch cone is not a "sea anchor," meaning something that you would use to anchor your boat to the surface of the sea, but is a drogue or a drag device. Most of the skepticism surrounding sea anchors in Coles's time can be traced to the attempted use of admiralty pattern cones by sailboats.

Closer investigation of the classic books and volumes written on the subject of heavy weather tactics will reveal the same misrepresentation. It seems that throughout the entire litany of sailing legend and tradition the term sea anchor was once used synonymously with miniature cone-type drag devices.

Having said that, modern publications are getting much better. In the 6th Edition of Heavy Weather Sailing Peter Bruce has devoted a whole chapter to the use of Drag Devices, and the case reports (using modern para-anchors etc) are much more encouraging, though he does still stress the need for 'further evaluation'.

Sailboats have deep keels that generate tremendous turbulence if pushed to the side. This lateral resistance makes the keel behave like a sea anchor when the boat is lying beam-to the seas.

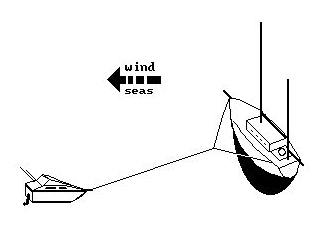

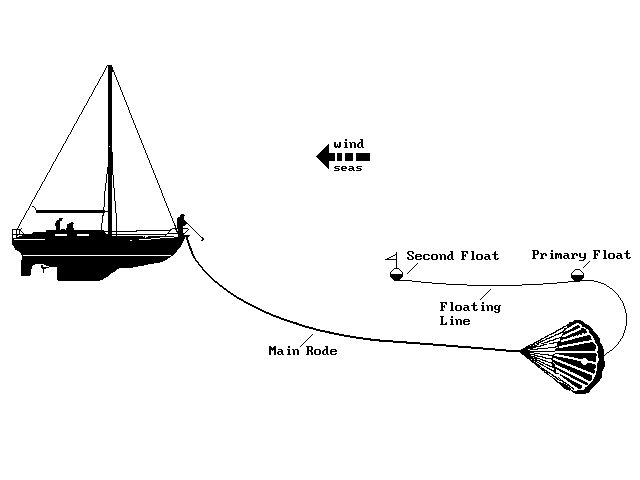

Immerse a three-foot diameter circle of plywood into a swimming pool and try to push it sideways. After several attempts you will appreciate the magnitude of the lateral resistance that even a small plane such as this is capable of producing. Sailboats have much larger planes. The image below dramatizes the point. The shallow-draft powerboat on the left is using the full keel of a stationary yacht as a "sea anchor."

With a draft of six feet, the full keel of a 36-foot sailboat will likely bite green water with turbulent force equal to that of a 4-6 foot diameter sea anchor. In this case, the turbulence generated by the keel (as the boat drifts slowly sideways in high winds) is some twelve times greater than the turbulence generated by a 21-inch diameter "admiralty pattern cone."

In point of fact, therefore, the yacht itself has a far better grip on the surface of the ocean than does the little cone. Axiom: A sea anchor must have a cross-section large enough to overcome the lateral resistance of the keel, before it can pull the bow of the sailboat into the seas.

This is why parachutes have such a good track record. They do what a sea anchor is supposed to do, by first overcoming the lateral resistance of the keel itself. In the words of Van Dorn, "In truth, aerial parachutes make the best sea anchors." (Oceanography And Seamanship, Dodd Mead, 1974)

Para-Anchor

It is not known who first lowered an aerial parachute into the sea from a boat. Quite likely it was a fisherman, for the sake of economic necessity. Fishermen don't like to return to port empty handed. "Breaking up a trip" because of thirty-knot winds is an expensive proposition. So they use parachutes to stay out and finish the work.

In Australia commercial fishermen use throwaway surplus parachutes, often putting out to sea with three or four on board. Pacific Northwest fishermen who brave Cape Flattery's stormy waters usually carry parachutes on board.

Fishing boats from Monterey, Mexico, use parachutes to maintain station and ride out bad weather. Generations of Indochinese fisherman have used large bamboo baskets to heave-to in the South China Sea. Many fishing junks and even large commercial fishing boats are now using para-anchors. Vietnamese fishermen who recently emigrated to the United States use Para-Tech sea anchors to heave-to in the Gulf of Mexico.

The term para-anchor itself was coined by Patrick M. Royce, author of Sailing Illustrated (Western Marine Enterprises, 1982). Royce undertook to conduct methodical tests on parachute sea anchors in 1964, and was probably the first to advocate their use on small craft (see pages 156-163 of Sailing Illustrated.)

Around 1970, Joan and John Casanova began advocating their use on multihulls, having used them on their own boats in the course of a twenty year, 200,000 mile cruise (see File S/T-1).

In the course of their many journeys Lin and Larry Pardey have used para-anchors to heave-to in numerous storms, and have developed a unique bridling system that they describe in many of their books, including the one entitled Storm Tactics Handbook (see Files S/M-3,4).

After several decades the term para-anchor is now in common usage. Safety experts, editors and writers use it to describe a wide variety of large diameter sea anchors, including military ordnance parachutes, 24-foot diameter army chest reserves, 26-foot diameter navy conicals, 28-foot diameter air force C-9s, converted skydiving parachutes, and other purpose-made sea anchors patterned after aerial parachutes.

Uses and Applications

Heaving-To: Heaving-to entails stopping the boat, bringing her into alignment and placing her in a defensive posture. The ways in which parachute sea anchors facilitate this are covered in the Sea Anchor files of this publication.

Reducing Storm Time: The average North Atlantic gale may have a diameter of about three hundred miles, and it may be moving at twelve knots, covering a distance equal to its own diameter in a day.

If a sailor can anchor his ship to the surface of the ocean he will likely emerge from the clutches of the gale in 24 hours. If he runs with it he may not be able to part company for three days.

Statistically at least, you can avoid two days of gale time - and umpteen big waves - by heaving to the para-anchor. Yes, you will end up arriving at your destination two days late. But so what. Better late than never. The gale may develop into a full blown storm and then it will be too late to think about ways of escape.

Drift Control: Many boats are lost annually when - initially disabled - they drift out of control and run aground. A para-anchor may enable you to hold your position and keep your disabled craft off the rocks long enough for rescue and a tow back to safe harbor.

Moreover we have all heard stories about the yacht that beat all night and in the morning the skipper found that he had not made good a single mile. In the words of Peter Blake, "no sailboat can go to windward in a storm."

Sometimes it just doesn't pay to beat into heavy seas. The wear and tear on the boat and crew does not justify the paucity of miles gained upwind. Sometimes it is wiser to stop and wait for more accommodating wind and seas. But to stop the boat may mean losing in a few hours the miles that you had suffered to gain in a full day. A para-anchor will enable you to hang on to those hard-won miles.

Damage Control: Most people who have never spent protracted periods of time at sea cannot appreciate just how difficult it can be to go about the business of repairing or pumping out a disabled boat this is rolling - rails buried - in the troughs.

A para-anchor can align the boat in such conditions, easing the motion and stabilizing the attitude. Repair work and pumping out operations then become a great deal easier and safer. Tip: In non-heavy weather - damage-control - situations the para-anchor can be deployed off the stern. Need to go up the mast to effect emergency repairs in the trade winds? Deploy the para-anchor off the stern, then you can do so in relative safety.

Safety Valve: For the shorthanded crew exhaustion, hypothermia and lack of rest are as dangerous as the sudden gale. Brain numb from lack of sleep and the whole outlook seeming bleak and hopeless, the shorthanded sailor will soon cross a dangerous threshold beyond which all is error, wrong judgment and wrong decision. It is precisely at this moment that the para-anchor is worth its weight in gold. Put out the chute. Call time-out. Get some rest. Then, you can get up to fight again, with your brain back in working order.

Safe Landfall: "Land is a mixed blessing," to quote the words of Webb Chiles. Heaven knows how many boats have successfully completed difficult ocean passages and then gone belly-up on the reefs because the skipper couldn't wait to set foot on dry land. If you make landfall at night and the harbor is unknown to you, or if the entry is a difficult one, our recommendation is as follows: Lay off a safe distance and wait for daylight. In areas where there are no currents and stiff winds blow night and day a para-anchor can be a most effective "parking brake."

Anchoring Offshore

Boats of every description have been riding out storms at anchor, inshore, since antiquity. When we read about a storm driving anchored boats aground we seldom hear anything about the ones that rode it out safely.

Case in point: The infamous gale that swept over Cabo San Lucas in December 1982 left a mangled mess of poorly anchored boats up on the beach, among them Bernard Moitessier's Joshua. But did you know that six boats, properly anchored, rode it out with little or no damage, all this in shallow water, with storm surge and huge breakers coming in?

Most sailing is done over water too deep to use a regular anchor. That is where a para-anchor must be used. A para-anchor turns the whole ocean into an anchorage of last resort, a wide open - private - anchorage with plenty of water beneath the keel, an anchorage free from the hazards of the "foul berth," an anchorage in which a sailor can pay out as much elastic rode as he wants and not have to worry about the perennial problem of swinging into other boats - or poorly anchored boats upwind dragging down on him, as happened to poor Joshua.

A Danforth anchor moors the boat to the seabed inshore. A para-anchor moors the boat to the sea-surface offshore. Unless the para-anchor is deployed in a current, there is surprisingly little drift involved. Many of the case histories listed in this publication include accurate drift rates that were obtained from GPS readings (the rates are listed in the summary section of each file). Some of these drift rates are in fact so low that one could say the boats were "anchored."

A para-anchor is a "portable mooring," used where the water is too deep to anchor the boat conventionally. It is generally used off the bow. No mariner in his right mind would use a Danforth to anchor a conventional sailboat stern to a storm. Likewise with the para-anchor, which is the offshore equivalent of the Danforth, Bruce or Plow. In truth, using a para-anchor offshore is a great deal like using a Danforth inshore. Many of the same principles apply. As with the Danforth, adequate yield and "give" must be incorporated into the system, otherwise some of the loads may exceed the limits of the components.

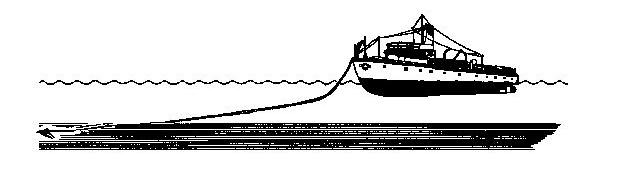

|

|

| Above are two views of Prisana II of Adelaide. Which end would you choose to present to the brunt of a storm? (Deborah Schultz & Stephen Edwards photo) | |

Forces Involved

The following information is from the American Boat and Yacht Council (ABYC). The numbers are subject to 101 caveats, are by no means the whole of the story, and should NOT be used as hard and fast standards. The table is presented here for the sole reason that many manufacturers refer to it to obtain some idea ("a ball park") about the sort of loads that might be placed on ground tackle in different wind and sea conditions. Loads are in pounds.

| Beam | Wind Velocity in kts | |||||

|---|---|---|---|---|---|---|

| LOA | Sail | Power | 15 | 32 | 42 | 60 |

| 10' | 4' | 4' | 40 | 160 | 320 | 640 |

| 15' | 5' | 6' | 60 | 250 | 500 | 1000 |

| 20' | 7' | 8' | 90 | 360 | 720 | 1440 |

| 25' | 8' | 9' | 125 | 490 | 980 | 1960 |

| 30' | 9' | 11' | 175 | 700 | 1400 | 2800 |

| 35' | 10' | 13' | 225 | 900 | 1800 | 3600 |

| 40' | 11' | 14' | 300 | 1200 | 2400 | 4800 |

| 50' | 13' | 16' | 400 | 1600 | 3200 | 6400 |

| 60' | 15' | 18' | 500 | 2000 | 4000 | 8000 |

Calculating forces on conventional anchors has never been easy. Calculating forces on para-anchors is all the more difficult. We will not drag out complicated force/vector formulae here. If the reader is so inclined he should consult other texts for such formulae, among them U.S. Coast Guard Report #CG-D-20-87 by Carol L. Hervey and Donald J. Jordan (National Technical Information Service, Springfield, Virginia 22161), the RORC-commissioned Report on Model Tests to Assess the Use of Drogues and Similar Devices to Prevent Yacht Capsize in Breaking Waves (Report #801, Wolfson Unit for Marine Technology and Industrial Aerodynamics, University of Southampton, Southampton, England S017 1BJ), and Daniel C. Shewmon's The Sea Anchor and Drogue Handbook (Shewmon, Inc., 1000 Harbor Lake Drive, Safety Harbor FL 34695-2310).

Instead of dragging out mathematical formulae we will instead try to focus on the seamanship side of the equation, that is, practical ways of taming some of the forces involved.

We will concentrate on principles and techniques which, when understood and applied, will reduce those forces as much as is humanly possible. One has to start out by saying that the modern fiberglass sailboat is built to withstand tremendous forces at sea.

As Fastnet '79 will bear witness, many of these boats can be rolled, capsized, thrown violently about, and still remain intact. The bow-cleat on such a boat can usually withstand several thousand pounds of loading. Modern drag devices, rope, chain, tackle and hardware can easily withstand similar loads if properly sized and properly used. Most of the forces encountered in a gale are within the "normal operational parameters" of boat and equipment. A few forces can occasionally exceed those limits and have to be watched for very carefully. What are they?

Wind Loading

The forces imposed on the hull and rig by the wind are ordinarily within the normal operating parameters of boat and hardware. They are the lesser of our worries.

Example: A 36-foot monohull may expose about 180 ft² of area to the wind when lying a-hull (mast & rig 45 ft² + hull 100 ft² + cabin 35 ft²), and 105 ft² when facing into the wind (mast & rig 45 ft² + hull 40 ft² + cabin 15 ft²).

At 60 knots sustained (Force 11) the wind imposes a force of about 12 lbs. on each square foot of exposed surface. The wind loading on this 36-ft. sailboat is therefore 2160 lbs. when she is lying a-hull (180 x 12) and 1260 lbs. when she is facing into the seas (105 x 12).

These figures are conservatively skewed. In reality they will be somewhat less. The rounded shape of a modern hull, for example, will mean a lower drag coefficient, resulting in lower wind loading. Bear in mind, also, that in Force 11 conditions large waves will tend to blanket out the wind when the boat is in a trough.

Aside from the destructive effects of microbursts (cold, dense air blowing straight down in a thunderstorm cell, knocking down any vessel with sails up), and aside from the possibility of the wind turning a multihull over by getting under the wings, wind forces on hull and rig have seldom been the cause of major failure and loss offshore. The culprit forces are usually others.

In the case of sailboats using sea anchors they are:

(1) Displacement force

(2) Divergence force

(3) Breaking waves

(4) Rogue waves.

There is much that a sailor can do to tame the first two. The fourth, rogue waves, can be summarily destructive but is mercifully rare. The acid test of any tactic, therefore, mainly involves the third, breaking waves, even though these are quite rare as well. Those of us whom Lady Luck has placed on the extreme "right tail" of the statistical curve of probability distribution may make many ocean passages without witnessing a single breaking wave.

Displacement Loads

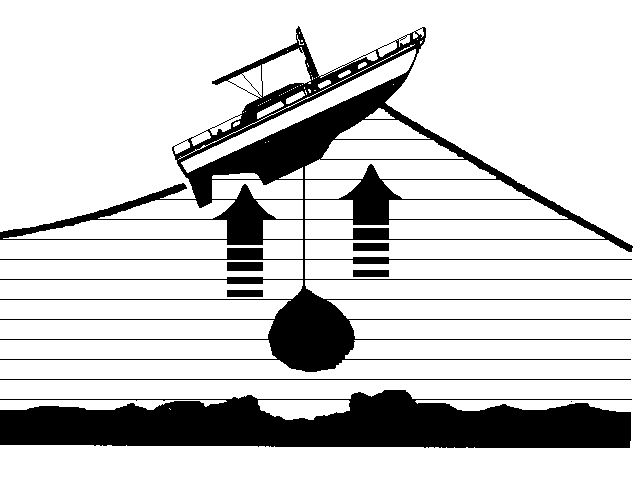

Displacement loads can be formidable - on an order of magnitude equal to the displacement of the boat, even on a windless day. In the case of an improperly anchored boat, displacement loads can instantly yank an anchor out of the bottom, bend its flukes, cause rope to snap like string, or even pull a large cleat out by the roots. The figure below is an oversimplified dramatization of the point. A 36-foot heavy-displacement sailboat has been moored to a 3-ton rock by means of unyielding steel cable. Question: What happens when a large swell lifts the boat? Answer: the boat will lift the rock right off the bottom.

Here we have a displacement load of 6,000 lbs. being placed on the mooring bit of a yacht on a calm and windless day. (Compare with a wind load of 1260-2160 lbs. in Force 11 conditions.)

The figures are from a booklet called Anchors and Anchoring and are reproduced here by permission of Rule Industries, manufacturers of world-famous Danforth anchors. The booklet was originally co-authored by Robert Danforth Ogg, progenitor of the Danforth anchor, and is still available from Rule Industries for the grand sum of one dollar (Rule Industries, Cape Ann Industrial Park, Gloucester MA 01930).

The figures were obtained by means of an electric load-measuring cell and tell the story in a language as plain as A, B, C. In only ten knots of wind the cell registered 6450 lbs. when the 104-ft. vessel was moored by means of 200 feet of unyielding steel cable. It registered 280 lbs. when a 70-ft. length of chain was incorporated into the cable, freeing the ship to rise and move with the waves - a 95% reduction in surge and displacement loads.

SOLID CABLE

Wind: 10 mph - Waves 2½'

Depth of water 25' - Scope 6.8 to 1

Load cell at bowcleat measured 6450 lbs.

70' CHAIN WITH CABLE

Wind: 10 mph - Waves 2½'

Depth of water 25' - Scope 6.8 to 1

Load cell at bowcleat measured 280 lbs.

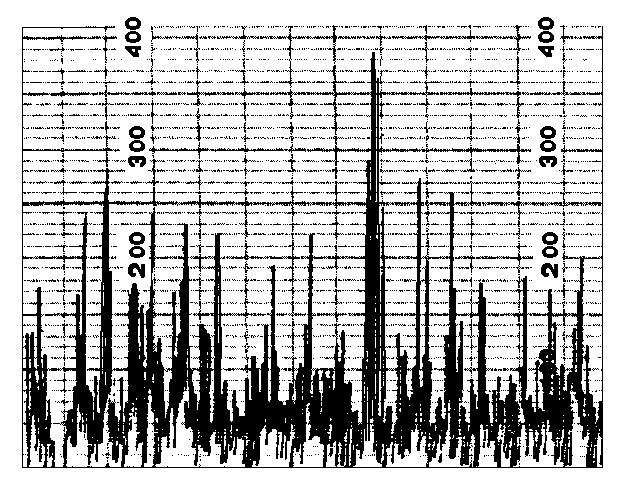

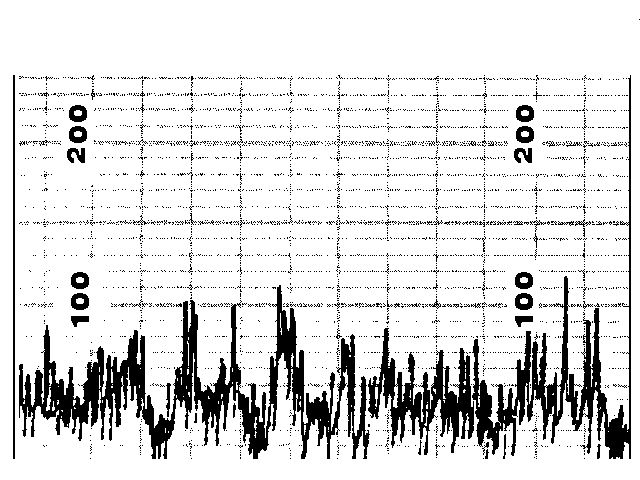

The graphs below show a similar reduction in peak dynamics loads, achieved by merely paying out more rode.

The tremendous value of long scope can be appreciated by noting the reduction of peak horizontal loads in the charts, recording with short and long scope on a 34-ft. cruiser offshore with a steady 25 knot wind and 6-8 foot seas.

The moral is this (quoting from the same booklet, Anchors and Anchoring, page 17):

The forces required to hold a boat in position solely against waves will generally be slight but only if ample freedom is allowed for the boat to oscillate with the waves. Allowance for this freedom is a major consideration in the proper design of a mooring or selection of anchor rode. Failure to provide this freedom may result in tremendous and even destructive surge loads.

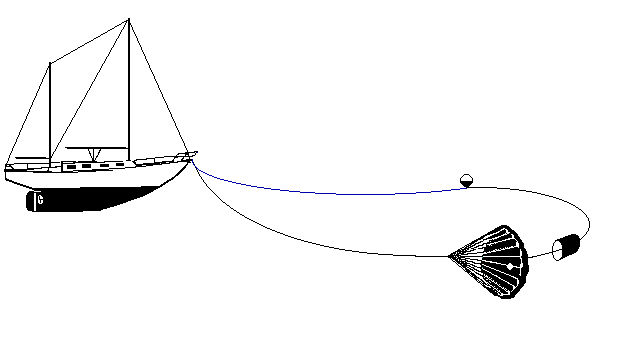

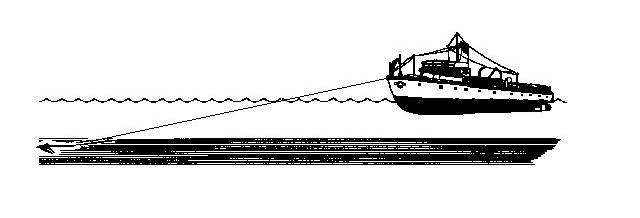

Displacement loads are principally encountered on vessels anchored to the seabed, though they can apply to vessels using para-anchors as well. Even though the rode is leading out to the para-anchor (instead of down to the Danforth), it may cause the parachute to interfere with the ability of the yacht to rise with the seas if it is too short (see Figure below).

Divergence Loads

Too short of a rode can put huge displacement forces onto the boat owing to the divergent direction of water movement at the peak and trough of a wave. Not also that the short rode interferes with the yachts ability to rise up on the wave. All in all a disastrous situation and probably the cause of the parachute failure in File S/P 1

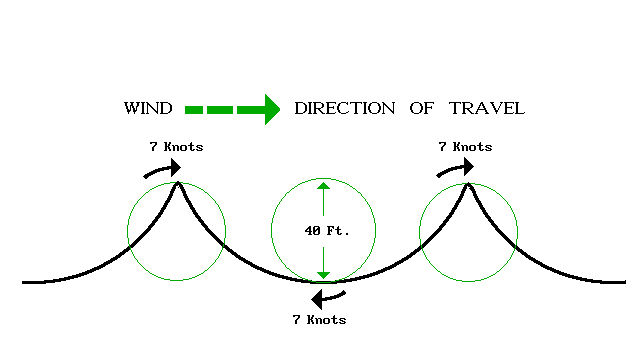

Divergence loads are encountered when boat and mooring move apart. They apply doubly to vessels using para-anchors. The Danforth obtains its purchase from the seabed, remains stationary, and cannot move back and forth in repeated cycles. The para-anchor, on the other hand, obtains its purchase from the sea's surface, which is frequented by waves. With the passage of each wave, the water molecules on the surface move in an orbit, causing the parachute and boat to move back and forth over real ground when viewed from above.

To get a clearer picture it helps to imagine that the parachute and the boat are situated on the rims of two adjacent flywheels, arranged like the wheels of a locomotive. The back and forth motion of the parachute and boat would then correspond to the horizontal motions of some imaginary piston, the rode playing the part of the piston rod. If the waves are twenty feet high, then each flywheel has a diameter of twenty feet.

As the first wheel goes round and round, it causes the boat to oscillate back and forth twenty feet (one diameter) when viewed from above.

As the second wheel goes round and round, it causes the parachute to do the same thing. So then, looking at the affair from above, and depending on the length of the rode, one might see the boat and para- anchor doing some "synchronized swimming" - moving back and forth in unison. Or, one might see them doing the "Charleston" - converging and diverging.

The moving water molecules set up a "rotary current" that flows downwind on the crest, and upwind in the trough. The approximate rate at which this "current" flows can be determined by dividing the circumference of the "wheel" by the wave period.

The force required to hold a sea anchor stationary in a three-knot current, for example, is the same as the force required to drag it behind a tug at three knots.

Tests conducted by Shewmon and Para-Tech have shown these forces to be far greater than was once imagined. In tug tests conducted by Para-Tech Engineering in San Diego Bay, for example, a sustained force of almost 6000 lbs. was required to drag a 12-foot diameter para-anchor (flat circular, zero porosity canopy) behind a tug at three knots. This gives some indication of the magnitude of the forces that may come into play if a heavy boat and a larger para-anchor are moving apart from one another at several knots.

The orbital surface current in a major Southern Ocean storm may amount to seven knots or more. One can easily envisage a short-rode scenario in which a heavy boat and a large sea anchor (laden with tons of water) move apart from one another at a combined rate of fourteen knots, causing the system to be "drawn and quartered."

The rope would snap. Hardware would let go. A cleat would pull out. The panels of the parachute would explode outward.

Or so one would hope. For if the components were indestructible the boat would likely end up being physically dragged through mountains of green water! Reminds one of the Hollywood spectacle of the hapless slave being dragged to death behind the Roman chariot.

Depending on their relative positions on the wave trains, the boat and the sea anchor may dance in step. Or they may do the "push-pull." If the latter is the case the rode will repeatedly tighten up, then go inexplicably slack. This can be a problem. At the very least it may cause a jerky motion, along with excessive yawing. In a worst-case scenario (extremely short rode) it may pull a cleat out, cause rope failure, or damage the parachute. Such things have happened in the past, but only when short rodes have been used.

In 1985, for example, the 60-foot trimaran Rogue Wave encountered such a problem in the Mediterranean. By all tokens the forces should have been within the limits of the boat's heavy duty hardware. But somehow they exceeded those limits. Hardware was pulled out, and the seams of the rugged Shewmon sea anchor being used were ruptured. After the incident Daniel C. Shewmon, founder of Shewmon Sea Anchors, Inc., wrote a paper entitled Sea anchor - Rode Tactics, explaining what happened (see Figure above, and also File D/T-3).

Divergence force explains some of the problems that commercial fisherman in particular have had with large parachutes. A disgruntled fisherman interviewed by Victor Shane in Monterey, California, for example, said that he was winching in a 24-ft. diameter surplus parachute in 8-foot coastal seas when, suddenly, "it started to pull my boat under."

The figure above tells the likely story. As the fisherman winched the boat closer to the parachute, it arrived at the precarious juncture where the ten-ton boat was being lifted up and moved back on the crest, while the parachute, containing tons of water, was moving down and forward in the adjacent trough a few feet away. The short, heavy anchor line could not stretch enough, giving the fisherman the impression that the parachute was trying to pull his boat under. So he fetched the knife and cut the rode.

As a storm develops the waves will begin to grow in size. Their lengths (crest to crest) will begin to increase as well. Depending on rode length, at a certain stage the phenomenon of divergence and convergence may make itself felt at sea anchor. If the wave lengths continue to grow the problem may go away by itself after a while.

Generally speaking, the more developed the seas - or the shallower the water - the more acutely will the phenomenon be felt. At times the rode will tighten up to breaking point, then go inexplicably slack, giving the impression that the parachute is alternately filling and collapsing. This can be a nuisance. It can also be dangerous. If the rode is too short and the waves are inordinately high, displacement load and divergence force may reinforce one another - recipe for certain disaster. Lady Luck may play a huge part here, however. A skipper may in ignorance have paid out only sixty feet of rode but, lucky for him, the waves just happen to be sixty feet from crest to crest. "Ignorance is bliss," as they say.

Usually Lady Luck favors the wise, the crafty and the prudent, however. By knowing the principles involved, and by compensating - making adjustments in rode length - a sailor can usually make the jerkiness go away almost immediately. However in the case of a multihull with a fixed bridle, adjustment may be impractical. More so, going on deck to adjust the rode in a full-blown storm may be out of the question altogether. What then is the solution? What can the wise and prudent sailor do?

At the very least a sailor can try to buffer all systems loads by supplementing the long nylon rode with a length or lengths of chain. Rigidity and inflexibility will not do in a storm. Forces must be buffered, or they will break something. Only Superman can withstand the forces of the sea without flinching. The rest of us have to try to come up with clever and ingenious ways of rolling with the punches. As the skydiving instructor tells his students: "When you hit the ground, try to roll with it."

Breaking Waves

Individual sea waves are ordinarily benign phenomena. If left alone, and given plenty of deep water to tread on, they may travel thousands of miles before depositing their packets of energy on a shore. The problem is this: they are not always left alone, and they do not always tread on deep water. Shoals, ocean currents, tidal flows, secondary wave trains and even the disturbance created by the wake of a large ship may interfere with the fluid motion of a wave and cause it to break prematurely, delivering a crippling blow to a sailboat that just happens to be in the wrong place at the wrong time.

Modern fiberglass hulls afford great protection nevertheless. They may be rolled around by breaking waves, but are greatly resistant to outright breakage. Some of the better built ones - Pacific Seacraft and Island Packet, to name just two - are all but indestructible.

As long as hulls can be kept afloat people can somehow survive inside them, even in the case of a capsized multihull. But the problem has seldom had to do with the failure of the hull itself. With monohulls in particular the problem usually starts with the failure of something appended to the hull - a mast, a rudder, a pilothouse, large windows, a weak hatch, or even large heavy objects such as batteries flying about inside. One thing leads to another and before you know it the situation is untenable and people are wanting to be taken off the boat.

Breaking waves need not render deathblows to sailboats. One must believe this. To believe otherwise is a sort of failure in itself. In very truth there is a great deal that a sailor can do to protect his or her vessel from the destructive influence of breaking waves. Many of the sailors featured in this publication have done just that.

By using a purpose-made drag device a sailor can greatly minimize the chance of his vessel being rolled - and dismasted. Prior measures can be taken to strengthen and reinforce masts, for example, so that they don't come down so easily.

And since broken masts have a reputation for doing-in otherwise intact hulls, hi-tech tools such as hydraulic wire cutters can be taken along to enable the crew to quickly and easily cut away a downed spar, before the sea can turn it into a lethal battering ram. Or stainless steel standing rigging could be replaced with modern super-fibres such as Dyneema Dux - stronger than steel, yet easily cut in an emergency.

Preparation is ninety percent of a mariner's labor. When it comes to breaking waves, a great deal can be done to prepare the boat beforehand. At the very least, measures can be taken to secure all items above and below decks. No responsible sailor will venture offshore with loose cannons on board - carelessly secured dinghies, tenders, anchors, spinnaker poles, batteries, large containers, jerry cans, appliances, cabinet doors, mirrors, glass items, drawers, floor boards, foodstuffs and the like that can vandalize a yacht in a gale and make it unfit for human habitation.

Securing everything above and below decks is doable. It should be the first order of business. And yet, for strange reasons (better known as human inertia and laziness) sailors procrastinate and vacillate and put off doing the work that needs to be done.

The authors are just as guilty as anyone else in this respect. We always seem to be sailing off with some important preparation work left unfinished. And then it is too late. A few big waves and the fiberglass dinghy becomes a life-threatening object. Climb down into the interior of any cruising boat and you will see all the loose cannons poised and ready to fly at a moment's notice.

In particular check the way the batteries are secured. If they are locked down by unassailable oak frames and thick stainless steel bolts then you will know that the boat is owned by a real seaman. If they are held down by bungee cords you will know otherwise.

Buffering The Loads

Given a seaworthy, watertight and well-secured boat, the parachute anchoring system affords a means of pushing back the envelope of survival a little further. It enables one to do a great deal to buffer the heavy blows of the sea.

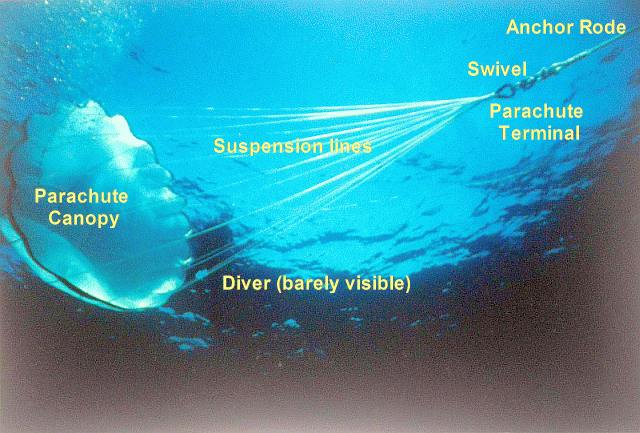

Indeed there is a great deal that is working in one's favor already here. To begin with, the para-anchor is deployed in a fluid - a yielding medium. It is fabricated from nylon materials, which stretch under load. If it is of flat circular construction, the very shape affords an added measure of flexibility as well. Unlike the rigid shape of a conical sea anchor, the canopy of a flat circular parachute can tense and relax. Victor Shane has seen the phenomenon close hand from helicopter and chase boats. The canopy looks very much as though it was some living creature - a huge jellyfish. It changes its shape. It seems to be "breathing." It expands into a rigid, flattish disk under load, then relaxes back into a looser, bowl-shaped affair in the slack cycles.

The fluid behavior of the parachute notwithstanding, the long nylon rode leading to it is an excellent shock absorber in, of and by itself. And there is even more: The shock absorption of the nylon rode can be significantly boosted by the mechanical - catenary - shock absorption provided by a length of chain.

Chain, properly used along with nylon rode, can be another bargaining chip in a storm. Chain will sink during slack cycles, helping to maintain system tension. This will reduce side-to-side yaw, which will reduce exposure. If a wave breaks against the hull the load will have to be transferred to the parachute via the elastic rode and sagging chain.

The force of the breaking wave will have to straighten the curve rapidly. The hundreds of links in the chain will then shed vortices, producing turbulence and building resistance. In effect the chain will then play the part of a "flopper stopper," sinking without complaint during slack cycles, but putting up considerable resistance when a sudden force tries to lift it up rapidly. Such an arrangement will go a long way to further reduce, buffer and mitigate any and all peak dynamics loads.

Allowing for suspect forces by the use of a long rode and chain tether, and by keeping a sharp eye on all short-rode applications, especially when retrieving a parachute in large swells (a full or partial canopy trip line should be used to avoid what happened to the Monterey fisherman), the mariner can use a para-anchor off the bow to align and restrain his boat in heavy weather, minimizing catastrophic events such as knock-downs, capsizes and barrel rolls.

There is only so much that even the most resourceful sailor can do, after which he will have to turn on the EPIRB. We are mortal.

Rolling With The Punches

What happens when a yacht is struck by a breaking wave? Everyone would like to know. The speculation is endless.

Books and a great many articles have been written on the subject. Model sailboats, looking very much like children's toys, have been subjected to "virtual storms" and "cloned waves" in test tanks.

Computer models have been used, and scientific papers have been published, adding bits and pieces to the sum of knowledge. And yet the whole of the sum remains elusive, because in a real storm no two breaking waves are exactly alike. Neither do they produce identical results. Moreover, even if real storm waves could also be "cloned," they would likely produce different results when striking different boats from different angles.

Being struck by a breaking wave is a little like being hit by a ten-ton avalanche moving at 35 knots. How is the boat moved by that avalanche? What sort of a reaction can one expect?

What happens in the ensuing seconds can determine the whole of the outcome. While a great many things can happen in those ensuing seconds, we can be sure of one thing: If the boat is under restraint of sea anchor the tension in the tether will build rapidly, hopefully to the point where it can pull the low-buoyancy bow back up in time.

The avalanche hits; the yacht is moved away from the sea anchor, pivoting on her CLR (center of lateral resistance) as she is being moved back; the tether builds up a reciprocal load and pulls the bow back up and over. If the line goes slack for some reason, the worst that can happen is that the bow will fall off temporarily. If another wave happens to break there and then, there is indeed a chance that the boat may get knocked down, capsized or rolled. In theory, however, there is a greater chance that the force of the impact will again take up the slack and rotate the bow back toward the origin of impact.

Whenever a boat is subjected to a large displacement of water, the sea anchor will try to pull the head around, irrespective of the influence of the wind. Take a toy sailboat, tie a string to its bow, place it in a stream and see for yourself. Anchor any boat in a river and the flow of water around the hull will align the vessel against the current, irrespective of wind direction. Since water is 800 times heavier than air, water alignment will always supersede air alignment.

The problem is this: in trying to align a vessel at sea, we have to make do with air flow most of the time. Since very few waves actually break, we are primarily relying on the wind to align the boat for us, and wind-alignment is a fickle business at best. The pressure of the wind against the topside, cabin, superstructure and rig is seldom constant in a storm. It may drop off in a trough, for example, allowing the bow to fall off.

No matter, if a wave breaks there will be real flow of water to align the axis of the boat against and direction of flow. Whatever shape the breaking wave may assume, in theory it can only capture and carry the boat a relatively short distance before she comes up short against the tether, which should - at a critical time - pull the bow up, over, or through the foamy upper portion of the wave.

Obviously this is not the case if the boat is lying a-hull, without a sea anchor system. Without the restraining influence of an adequate sea anchor the boat may be "taken for a ride," flung violently onto her beam ends, capsized, or even thrown end over end.

Victor Shane's Personal Experience

Shane's understanding of sea anchors and their many uses came by way of not too little white-knuckled experimentation in the windy Santa Barbara Channel, beginning in 1976.

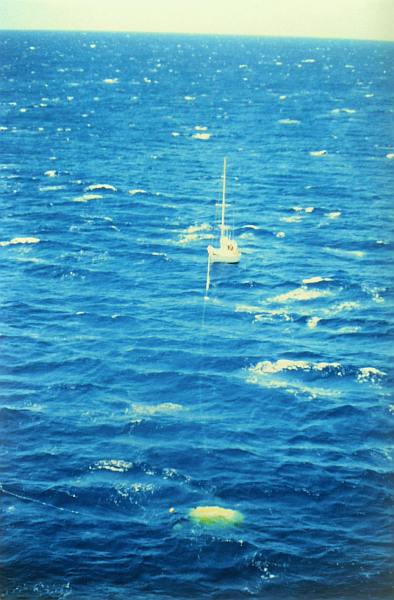

The experience paid off later when he sailed a little trimaran to Hawaii and back in the summer of 1979. The boat was a 24-foot Piver Nugget, a 1200-lb. daysailer - "glorified outrigger," to quote the words of harbormaster of Hilo.

Three hulls, built out of quarter inch plywood. No hatch. Just a canvas curtain to keep the sea out of her cuddy cabin. Providence was her name, and she is to date the smallest multihull to have been sailed back from Hawaii singlehanded. An "adventure" to be sure, and yet that adventure would have turned into an ordeal had it not been for the drag devices that Shane took along - several parachutes and a number of makeshift drogues.

Ordinarily a boat like Providence has a very limited cruising envelope. The drag devices had the effect of pushing back that envelope, making possible a major ocean passage. On the first leg of the journey, for example, Shane used a 9-foot diameter para-anchor to heave-to in the outer coastal waters of California, gale-force winds advisories being in effect on VHF and WWV for a region extending from Monterey all the way to the Mexican border!

Later on in the trip he used the same para-anchor for heaving-to and for damage control in large chaotic seas generated by a combination of reinforced trade winds, vicious squalls, and big swells originating from a tropical storm named Dolores.

For five days, from a distance of five hundred miles, the lady Dolores stalked the Providence across the Pacific, making life miserable for boat and sailor, as though life in the cold, lumpy, gray, overcast trade winds was not miserable enough already.

One day out of Hilo Shane used the para-anchor for drift control - to engineer daylight landfall. Three weeks later he used it again in the Isthmus of Maui to bring the head of the boat up into 30-knot afternoon winds, in order to hoist and double-reef the mains'l - ever try hoisting a main in thirty knot winds without an engine to bring her up into the wind?

The Isthmus of Maui is shaped like a mountainous funnel that faces into the NE trade winds. On the afternoon of 11 August 1979, Providence was caught in that funnel with her mains'l down, trying to beat her way out with a working jib alone.

It was on that afternoon that the wind, the sea, Murphy and the devil did their very best to impale her on black rocks awash. It was touch and go for a while, the boat side-slipping, the rocks looming closer and closer, Victor Shane trying to force the tiller, paralyzed with fear and sweat pouring down his face. But the para-anchor saved the day. It enabled him to call "time out" and stop the boat long enough to hoist and double-reef the main.

With waves crashing on nearby rocks and the double-reefed main flogging and cracking like a shotgun, Shane backwinded the jib. The little trimaran turned away from the rocky grave. Thereafter she began beating her way out of the Isthmus of Maui with a bone in her teeth, like a champion, windward float flying and her bow shaking off spray like that of a battleship steaming into a gale.

An hour later she finally rounded the north-eastern tip of Maui and, easing her off the wind, Shane was able to breathe a sigh of deep relief, now sailing smoothly on crystal clear water, magnificent coral heads visible below, steering a course for the calm anchorages situated on the sheltered side of that magnificent island.

The Fastnet tragedy of that same year occurred a few days later when Providence was tied up in Black Manele Bay, on the island of Lanai. Shane first heard the news while listening to the BBC on the short-wave radio, and it was disheartening news indeed, not only for him, but for all the other boats tied up there too. It made all of them stop and wonder about the whole business of "cruising." And it made the prospect of sailing that little plywood trimaran back to the mainland seem all the more impossible, all the more foreboding for Shane.

Notwithstanding, on Friday 30 August 1979 Providence rounded the western tip of Oahu and, with a fresh bone in her teeth, began the long, arduous beat back to California.

The specter of the Fastnet tragedy haunted Shane throughout the entire voyage, never giving him a moment's peace - just as well, because on 22 September 1979 Providence ran into a gale 650 miles northwest of San Francisco.

He was well prepared, however. Shaking his fist at the sea and railing none too kindly at the wind, as is the custom of singlehanded sailors, he had the para-anchor deployed, the rudder tied, the sails off, everything battened down and chafe gear in place in record time.

Lying to a sea anchor in a gale at night, one gets a feel of what is going on through the seat of the pants. A thermos full of hot tea laced with honey and rum has a way of putting things in perspective well.

At times one becomes part of the boat, able to anticipate every action and reaction, every strain and stress, every complaint and protest. And it is not long before one gets an appreciation of the way in which the boat is rolling with the punches.

Most of the time she does so by pivoting in place. Contrary to popular opinion, a sailboat at sea anchor does not recoil or kick back like the barrel of a cannon, when hit by a wave. No, the reaction is nearly always rotational. Mostly, she pivots on her CLR (center of lateral resistance), parrying the blow of the sea like a Kung Fu expert.

This is what happens: First she rises smartly to the crest (not so much because of her buoyancy, but because of the elevator effect of the orbital rotation of the wave itself). As the crest hits she pivots briefly, as though to parry the blow. Then she faces front again. If there is unstable water at the crest then that is when one hears the loud, hollow "thunk" and feels the boat pivot and tug on the nylon tether, which then pulls - rotates - the bow back into the seas. It is a noisy affair, and the slapping and banging sounds are enough to drive a sailor mad at times. And it is uncomfortable in a small boat. There is roll, there is pitch, and none too little of the business of hobbyhorsing. But the predictable reactions of the boat have a way of instilling confidence in the mind, in spite of the noise, the discomfort, the cold, the wet, the worries and the fears.

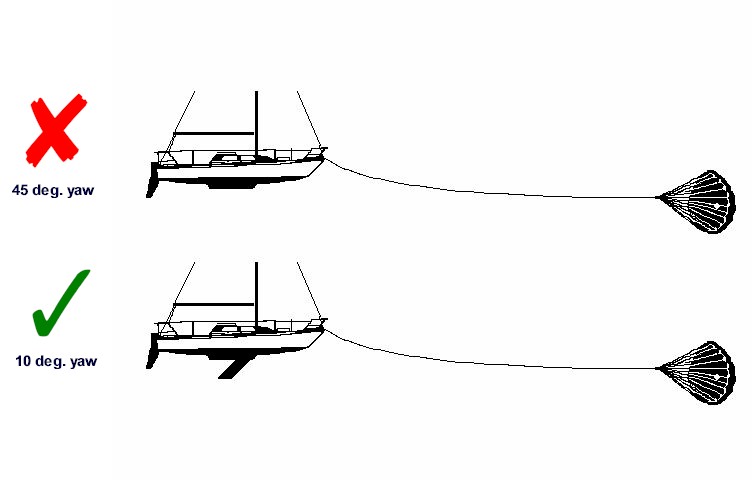

Ordinarily a vessel held to a sea anchor yields to an advancing wave by rotating on her CLR. This produces uncomfortable side-to-side yaw, and conventional wisdom has it that side-to-side yaw should be avoided at all costs. While excessive side-to-side yaw is indeed undesirable, the ability of the yacht to pivot on her CLR may be a blessing in disguise. To be sure it produces some discomfort, but one should not confuse safety with comfort.

In principle the mechanism is not too different from that of the suspension arm of an automobile, only here the yacht's CLR is the pivot point, and the stretch of the nylon rode is the shock absorber. As in the case of the automobile suspension, the bow does not have to be deflected a great distance to absorb the shock, but the short distance that it does move is critical (the entire frame of an automobile would be irreparably damaged without those shock absorbers).

The idea that a sea anchor works by keeping the bow of a vessel snubbed 100% into the teeth of a gale is a fallacy. That's not how a sea anchor works. Every sailboat has a CLR, which is the fulcrum around which the force of an impacting wave is initially translated into turning moment. The yacht pivots, parrying the blow with the point of her hull, stretching the nylon rode, which then pulls and rotates the bow back towards the origin of impact.

If the reader will forgive the pun, the theory of bow-deployed sea anchors "hinges" on the yacht's CLR. Given the fulcrum of the CLR, the para-anchor and the elastic rode work together to keep the yacht aligned in spring-loaded fashion, producing a strong restoring force when the boat tries to fall off the wind and lie beam to the seas. This restoring force is most effective on multihulls having recourse to wide bridling systems. It is less effective on some monohulls. But even on the most difficult of monohulls it is a decided improvement on the foolish practice of lying a-hull in storms.

Things You Will Need

Sea Anchor: See Appendix III at the back of this publication for a list of sea anchor manufacturers and providers. Although independent, Shane has worked closely with a number of drag device manufacturers, principally Para-Tech Engineering in Colorado, formerly in San Diego, and the authors are in contact with others regarding the DDDB program.

Throughout this publication the authors use parachute industry standards for determining diameter. Diameters indicated are therefore nominal, and not inflated or, as the British parachute rigger might say, flying diameter. For an exhaustive listing of parachute industry nomenclature and standards see The Parachute Manual, by Dan Poynter (Para-Publishing, 1984). Some manufacturers use different standards for determining sea anchor diameter.

U.S. SAILING's Recommendations For Offshore Sailing suggests that, as a general guideline, the diameter of the parachute sea anchor be at least 35% of the LOA (length over all). This is a good ballpark figure. Sea anchor sizing is not a precise art, however. Refer to manufacturer's recommendation for sizing. When in doubt err on the larger side. In the authors' opinion there is no substitute for diameter. The larger the para-anchor the more reliable its grip on the sea, the less the chance of it being tumbled by surface action, the better the behavior of the boat, the lower the rate of drift and the less the strain on the rudder and its fittings.

A possible exception to this rule may involve the Pardeys' method of heaving-to, requiring that keel generate some turbulence of its own (see Files S/M-3 & 4). Even so, the Pardeys themselves have always used medium size para-anchors and have never advocated the use of "21-inch diameter admiralty pattern cones." In the authors' opinion, trying to reduce system loads by choosing a smaller - "more yielding" - sea anchor is bad logic. Earl Hinz has this to say about it in Understanding Sea Anchors and Drogues:

Some writers say that they want a sea anchor with `give' to it - they don't want to be held firmly against the impact of a wave. The idea that a properly sized sea anchor will `give' with the wave is patently untrue. The large mass of water in a sea anchor cannot be accelerated rapidly enough to absorb a wave's impact on the hull. A small sea anchor only lets the boat drift to leeward faster and yaw into a broaching position. As the sea anchor becomes smaller and smaller, the boat begins reacting more and more like a boat that is lying a-hull.

Did you ever think that a larger ground anchor would transmit increased loads to your boat? Certainly not; all it does is assure that you have a more positive grip on the seabed. Similarly, a larger sea anchor gets a better `bite' on the water and is in a better position to withstand constant loads of the wind on the boat. The strains on tether and hull will be no greater than with a small sea anchor that is not slipping. In fact, a small sea anchor that lets the boat yaw excessively will cause a greater strain on the boat when a wave hits it broadside at its greater angle of yaw. (From Understanding Sea Anchors and Drogues by Earl R. Hinz, copyright - 1987 by Cornell Maritime Press, Inc. By permission.)

Nylon Rode: Adequate "scope" must be paid out to leave the yacht free to rise and rotate with the waves and to buffer the shock forces involved. Generally speaking, the longer the rode, the less the strain on the system. For heavy weather applications it is suggested that the length of the nylon tether amount to about ten times the length of the boat or a minimum of 300 feet, whichever is greater. This is a basic rule of thumb which was first proposed by the Casanovas.

Ideally speaking it would be more "scientific" to relate the length of the tether to the height of the waves, as does Daniel C. Shewmon. Wave heights - and lengths - can quickly change in a developing storm, however. Moreover it is very difficult to determine wave heights after dark.

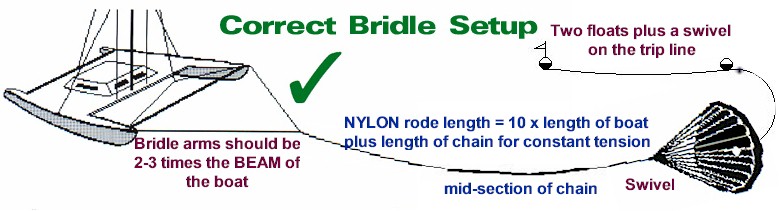

Tethers must have thimbles spliced into both ends (use stainless steel thimbles, and always whip, serve, tape and secure the thimble in place). In addition to the main tether, multihulls must rig a full-width, symmetrical bridle, one that leads from the tips of the outer hulls or floats. Side-to-side yaw can be greatly reduced on multihulls by means of such a bridle. The multihull bridle-tether looks like an inverted "Y" . It is generally agreed that the length of each bridle arm should be 2-3 times the maximum beam of the multihull, and that the length of the tether itself should be at least 10 times the length of the multihull.

Some sailors use their existing anchor lines for sea anchor tethers. There is nothing wrong with this, as long as the line is fairly new, in good condition and up to the task. Other sailors prefer a dedicated sea anchor rode. It is best to go with higher quality if purchasing new rope. Better ropes have higher strengths and come with high-tech coatings that can reduce chafe. Cheap, hardware store variety ropes, especially automotive polypropylene "tow ropes" should be avoided.

In the meantime the controversy between three-strand and braid rages on. Some sailors swear by one - and at the other. Three-strand is coiled like a spring, is easy to inspect, and affords more stretch - up to 30% and more. But it is stiffer, chafes through more rapidly, and torques under load - as it tries to unlay. Three-strand has been known to kink and hockle. Braided nylon has less stretch - up to 15% and more - but is easier to handle, easier to store, seems to be more resistant to chafe, and is torque-free. More importantly, braided nylon can be up to 45% stronger than three-strand for a given diameter. The commercial half-inch three-strand sold at downtown hardware stores, for example, may be rated at about 6000 lbs., whereas Pelican's premium double braid half inch is rated at 8,500 lbs. Always check rope manufacturers' specifications.

In general, rode diameters should be the same as ground tackle rode. Try to avoid overkill. The security afforded by one-inch line is more than offset by the lack of stretch if the boat is a J-30, for example. A forty-ton schooner may be able to stretch one-inch nylon line. Not so a J-30.

The parachute anchoring system relies heavily on buffered elasticity. One wants a rode that is always loaded enough such that it is stretched and providing restraint, but still within recoverable elastic limits. Using one-inch braid on a J-30 would be tantamount to using steel cable. The boat would be "held" all right, but the spring would not spring and the entire rig would take a severe beating. At the other extreme one would not want to use quarter-inch three-strand on a J-30 either. Why not? Because even if was of adequate strength it could still be stretching as the boat was being capsized. A compromise has to be struck between strength and stretch. Sometimes this is not an easy compromise to make.

Example: It takes a sustained load of about 8000 lbs. to stretch brand new half-inch nylon braid to its limit. If the wind loading on a 36-ft. yacht is about 2000 lbs. in a storm, does this mean that the rope is always 25% loaded? In theory yes. In practice no.

Orbital rotation in the trough, along with the blanketing action of big waves will create slack, which will reduce the loading. Alternatively, a breaking wave will rapidly increase the loading.

Regardless, what we are aiming for is constant tension, a reserve of strong elasticity part of which is in constant use, a spring that is partially deflected all the time. This sort of model cannot be achieved with short rodes, or with rodes that are too heavy. It takes a long, properly-sized rode to obtain the desired result. We want a spring-loaded affair, with the spring seldom bottomed out at either end. This will result in better alignment, less side-to-side yaw, and lower peak dynamics loads. Notwithstanding, chain can be a great help, even in the case of oversized rope.

Chain: Although some sailors will prefer to forego the chain altogether, it will help keep the system spring-loaded, regardless of the stretch of the nylon rode itself. An all-chain tether is not recommended. At least half of the tether should be nylon. Ten fathoms (sixty feet) of 5/16" chain will likely do for a J-30 hove-to in a bad gale. A Westsail 42 could probably do with 100 feet or more of 3/8" in a storm.

How much chain depends on wind force and the peculiarities of the boat. The thing to do is to keep an eye on the angle at which the tether leads down. Too much chain in too little wind will result in the tether leading almost straight down. If the tether is leading straight down there will be no horizontal pull on the bow cleat and the loss in tension will allow the boat to lie a-hull.

If they decide to use a length of chain, multihulls may incorporate the chain between the bridle and tether. One hundred feet of chain did wonders for a 42-ft. Crowther catamaran in a severe North Pacific storm (see File S/C-6B).

Smaller monohulls without windlasses can incorporate the chain mid-scope - or use a heavy rope snubber to bring the chain on deck. A snubber is a short length of sacrificial rope, about ten feet long, with a steel chain hook on the end. Chain hooks are specifically made for 5/16", 3/8" and 1/2" chain (available through West Marine). Although the hook engages the chain somewhat superficially, it has seldom been known to come off under tension. Nylon or Dacron snubbers are a must if there is any possibility of the chain "sawing through" something. With a little creativity, chain can be incorporated into the parachute anchoring systems in any number of ways.

Some writers advise that the chain be hooked up at the sea anchor end. While this idea may have merit in a hurricane, it may also allow the sea anchor to sink too deep - as the eye of the hurricane passes over and the wind briefly fizzles out, for example. Unless adequately buoyed, in the few minutes that it takes for the eye to pass overhead the sea anchor may sink to the depths and afterwards interfere with the ability of the yacht to rise with the seas (displacement loads again). This is why Victor Shane personally prefers to incorporate the chain elsewhere, either mid-scope, or next to the boat itself.

Larger monohulls with heavy duty windlasses have a decided advantage. The owner can attach the bitter end of the para-anchor rode to the existing anchor chain and pay out as much as is necessary, sometimes by the push of a button. This is quite convenient, but be sure to remove the steel anchor beforehand. Letting the steel anchor out as part of the system may be asking for trouble in a big storm.

Although many sailors do this because it is very convenient, and even though the added weight of the anchor improves mechanical shock absorption, the benefit is not worth the risk, in the authors' opinion. The steel anchor may get thrown against the boat. It is best to take the steel anchor off. In the Queen's Birthday Storm a huge wave picked up a drogue and 200 feet of rode and bridle and threw the whole kit and caboodle onto the stern of the catamaran Heartlight. Food for thought.

Anchor chain comes in three classifications: Proof, BBB and high-test. All can be used, though high test provides more strength for a given weight and storage volume. When purchasing brand new chain make certain the links will fit on the capstan's gypsy or chain wheel (many windlass manufacturers specify the chain type that needs to be used). Make sure also that the link welds are properly done - the authors have seen links just break apart at the weld, even under low load. See Appendix IV at the back of this publication for strengths and working loads on chain and related hardware. See West Marine's big catalog for a wealth of information on chain, hardware, rope and everything else (West Marine, P.O. Box 50050, Watsonville, California 95077-5050).

Hardware: Make certain there are no weak links in the system. The extent to which sailors turn a blind eye to weak links is truly amazing. Walk down the dock and note all the $2 galvanized shackles that are uniting $500 CQRs with hi-test chain on $75,000 yachts. Admittedly chain is not easy to hookup. The links on hi-test, for example, are far too small to accommodate the pin of a shackle of equal strength. The sailor who is in a hurry is sorely tempted to use a small union shackle - with a quarter of the strength of the chain. Resist this temptation. Union shackles must have strengths that match other components. There are a number of ways of getting around this. Higher strength stainless steel chain shackles for one. Or specialty fittings available through marine catalogs - always check their load rating. Lok-A-Loy fittings, manufactured by Crosby Corporation for the logging industry, are specifically made for the purpose of connecting chain to rope.

Although they tend to rust after a while, Lok-A-Loys are in widespread use by commercial fisherman. A 3/8" Lok-A-Loy (used to connect 3/8" chain to rope) has a safe working load in excess of 7000 lbs. - the equivalent of a 5/8" galvanized shackle. (Crosby Corporation, P.O.Box 3128, Tulsa, Oklahoma 74101-3128).

Titanium fittings are slowly showing up on the market. Titanium is used in the manufacture of critical components on fighter aircraft and nuclear submarines. It feels like aluminum but is corrosion proof and far stronger than stainless steel. The 3/8" titanium shackle made by Suncor Marine, for example, has a safe working load of 7500 lbs. (Suncor Marine and Industrial, Inc., 7 Riverside Drive, Pembroke, Massachusetts 02359).

Another option is the use of Dyneema rope - a 1/4" 12 strand line has a breaking strength of about 9,000 lbs, floats, and is remarkably abrasion resistant too. It can also be used to make simple and quick soft shackles that can then be used to assemble the parts of your sea anchor system.

Attachment Points: Heavy duty cleats, bollards, padeyes, through bolted with backing plates, should be used for attaching the tether. The rule is OVERSIZE, OVERSIZE, OVERSIZE. When purchasing cleats, for example, purchase the larger - ten or twelve inch - stainless steel Herreshoff cleats that require four bolts. Stainless steel anchor rollers should be OVERSIZE as well, with no more than four or five inches of overhang. Make certain the roller has a securing pin to keep the rode from jumping out.

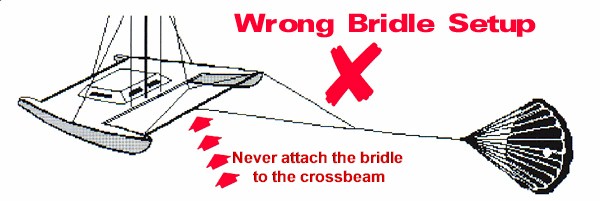

Many modern catamarans come with a single anchor roller affixed to the middle of the relatively week aluminum crossbeam that holds the trampoline up. This roller may be convenient for anchoring a cat in moderate conditions, but is not recommended for storm anchoring. There is a strong possibility that the failure of this aluminum crossmember may have resulted in the tragic capsize of the catamaran Bayete in a Mediterranean Mistral (see File S/C-19).

CAUTION: Catamarans should use full-width symmetrical bridles anchored to the strong hulls themselves. Ensure that the attachment point is STRONG. Dave Abbott of Exit Only gives an example of how to beef up the bow attachment on a catamaran (scroll down to the bottom to find his schematic for how to make it yourself).

Chafe Protection: In the authors' opinion chafe is the principle gadfly of the parachute anchoring system. To avoid this gadfly the Casanovas ended up shackling the bridle to custom-made stainless steel bails on the floats of Tortuga Too (see File S/T-1), similar to Dave Abbotts system just described.

Unfortunately, shackling the rode to large outboard eyes on monohulls is not practical - unless one is dealing with a steel boat. Monohulls are stuck with having to bring the rode to a cleat on deck, and it always ends up rubbing against something en route to the cleat.

This contact point is where most of the chafe takes place, not at the cleat itself. Chain solves much of the problem, although it has been known to literally saw boats in half in hurricanes. A heavy Nylon or Dacron snubber would greatly reduce such a possibility.

Nylon chafes through much more rapidly than Dacron. The stretch that provides shock absorption also produces chafe at any contact point. Stretch and relax a rubber band across the edge of a table repeatedly. This is the "sawing effect" that causes chafe. Now try it with a piece of string. Dacron does not stretch as much and is more immune to chafe.

Perhaps it would make better sense to make our snubbers out of heavy Dacron - or even Kevlar. Three-strand chafes through quicker than braid - once the "knobby high points" are gone the rest of the line will chafe through very quickly.

With a tightly cleated line there is very little chafe at the cleat or bollard itself. Ditto tightly knotted mooring rings. Maximum chafe always takes place where rope is free to move about - usually at a chock. The farther away the chock is from the cleat, the greater the chafe. In a storm, a chock that is six feet away from a cleat becomes a deadly rope cutter.

Never doubt that the heaviest rope can chafe through in a matter of minutes in a storm, if it is left unprotected on a chock. Concerning chafe the best advice the author can give is this: Don't take anything for granted. Use several layers of redundancy. Use anything it takes - discarded firehose (call your local fire station), heavy duty garden hose, reinforced plastic hose, leather gear, rags or even grease. In olden days sailors were handed buckets of grease and assigned stations at the chocks of a ship in tow.

Even so, never assume that the protection is going to stay in place. Garden hose is notorious for migrating away from the chafe point. Freshen the nip when everything else fails - let out a few inches of line every so often to shift the wear point and reduce localized chafe. The best arrangement the authors have seen is on commercial fishing boats: a chain bridle, encased in firehose.

Rudder Considerations: One of Victor Shane's first concerns about the parachute anchoring system was rudder vulnerability. Almost four decades later, it is much less of a concern. If the sea anchor is large enough it does not appear that the strains placed on the rudder/s will exceed normal limits. Most fears about "drifting down on the rudder" are unfounded, as Joan Casanova confirms in File S/T-1.

Boats do not drift down on their rudders at anchor. They may surge back, but they do not drift down. Notwithstanding, weak rudder assemblies are at risk in a storm. Then again, everything of a weak nature is at risk in a storm. If your rudder breaks in a gale - several "exploded" during Fastnet '79 - will you be able to jury-rig a substitute? With the right tools, some nuts and bolts, a bunkboard or two and an oar handle you could do so. No matter, if the rudder breaks it breaks. Rudders are replaceable. Lives are not.

Tillers should be secured amidships with several layers of bungee to allow a little "give." Shane lashed two layers of quarter-inch bungee for Providence's small tiller. The tiller on a Westsail 32 will likely require five layers.

Although most wheels can be mechanically locked it is better to use a similar bungee restraint somewhere down below, perhaps on the quadrant itself. Strains on wheel systems are always a source of worry in a storm. "One of the most common failures during rough weather is metal fatigue in the steering cables leading to the wheel," write the Pardeys in Storm Tactics (page 103). Vessels with wheel steering should have easy access on deck to a shaft head to which an emergency tiller can be attached for back-up steering.

Don't put out to sea without this sort of a backup, and make certain your emergency tiller is big enough and hefty enough for ordinary, everyday steering. The little two-foot aluminum club won't do.

Here is some more good advice: Devise a way of leading steering lines directly to the rudder itself. Many old salts do this. Some install padeyes or eyebolts above the waterline, others bolt a flange to the blade down below.

Victor Shane installed padeyes on Providence's transom rudder and they proved invaluable in the journey to Hawaii and back. The steering pulley fell off its shaft in the outer coastal waters of California and it took all of sixty seconds to restore backup steering. Old sailing ships had five-inch round holes cut out in their rudders, for purposes of attaching emergency steering rope.

Centerboards & Swing Keels: v CAUTION: Lowering board/s and keels, or lowering them all the way, may give the yacht something to trip over. By and large, and as an important rule of seamanship, boards and keels should be raised in storms so that the yacht can "slip-slide," and not have something to trip over.

However, certain small monohulls may need to lower - or partially lower - the swing keel, in order to reduce side-to-side yaw. When the swing keel is fully raised on a smaller - trailerable - monohull, the CLR moves all the way back to the plane of the rudder. As the boat surges back at anchor it "trips" on that plane, causing the bow to fall off to either side and yaw excessively - see File S/M-11.

On such boats, swing keels and boards can be lowered at sea anchor, to reduces side-to-side yaw. They can be partially lowered to provide less of an underwater appendage for the yacht to trip over in a gale.

Additional Things: Life jackets, flotation vests, safety harnesses, jacklines, whistles, etc. are absolute necessities. Don't even think about venturing on deck in a gale without safety harness and life vest. A good pair of sailing gloves will make rope handling less painful. You may find it easiest to use the ones that leave the tips of the fingers exposed (for handling tools, fittings etc.)

When working on deck in a gale one is usually on one's knees, and this is where a good pair of knee pads can make a big difference. Purchase knee pads sold in hardware stores - the one's worn by bikers and skaters don't quite fit the bill.

Often the force of the wind and/or driving spray makes it very difficult to look straight ahead in a gale, so eye protection is a must. At the very least diving goggles will do. Inexpensive safety goggles are better than nothing. Ski goggles are better. Racing goggles are best, and excellent ones are made by Uvex. Uvex goggles are used in outboard racing, the boats attaining speeds of 200 mph on lakes. They cost around $70 and come in two models, one of which can be worn over eyeglasses (available from Lifeline, 1601 Kofa Avenue, Parker, Arizona 85344).

In the course of traversing great oceans one can usually journey for weeks without seeing other vessels, and the whole ocean can be one's own private anchorage, so to speak. In coastal waters the situation may be different.

If deployment takes place in the vicinity of other craft (commercial fishing boats, for example) you are required to let them know that you are "at anchor." When anchored to the ground this is done by showing the proper shape by day, a black ball in this case (SKU # 203646 in the West Marine catalog), or an anchor light by night.

However, being anchored at sea does not fit the COLREG definitions of being at anchor, and a black ball would not doubt confuse people way out at see. In those situations, the correct signals are TWO black balls by day, and TWO red lights (one above the other) at night - vessel not under command. In practice, however, few yachts are able to conform to those signals, in which case a bright all-round white anchor light is better than nothing. If you have an AIS transmitter, keep it on, and be ready with a bright white flare in case anyone comes too close.

Along with the VHF a bullhorn can be a great help in tight quarters.

Commercial fishermen have been known to run over para-anchor lines. A submerged sea anchor and its long rode is not easy to see and the whole idea of a boat being "anchored" offshore is new. One should therefore remain alert and adopt a responsible attitude about warning other vessels. It is better that you take on the initiative yourself, and not leave anything to chance. At the very least observe existing regulations. Then you can say that you were in conformity.

Caution: Do not deploy a large sea anchor in the axis of a major current unless it is absolutely necessary. Ocean currents are a mixed blessing. The free ride that they may provide can be very costly in a storm. Try to traverse the current at right angles and get well clear before deploying the sea anchor.

WARNING: Do not deploy sea anchors inside shipping lanes! You may get run over. Victor Shane knows whereof he speaks, and will never forget the pitch black night in which he woke up to the smell of diesel fumes in the middle of Pacific and was terror-stricken by the proximity of something huge and wall-like sliding by. Large container ships carry millions of dollars of cargo and are on very tight schedules. They are not looking out for little sailboats. Their radars are set to warn them about other large ships. They could not stop for you if they wanted to.

Statistically speaking the hazard of collision increases year by year as more and more container ships - and cruising sailboats - ply the high seas. Most container carriers stick to the shipping lanes to conserve fuel, and most collisions take place in those shipping lanes. Major shipping lanes are clearly marked on Pilot Charts - the great circle routes. Don't put out to sea without Pilot Charts. Ask for them by name. Mark the great circles routes with a yellow hi-liter and transcribe them onto your regular charts.

Stay awake when crossing shipping lanes. Set several alarms, especially if you are singlehanded. A thermos of the blackest coffee is called for here. Don't fall asleep, as Shane did. In the thirty minutes that you are dozing a container ship the size of an aircraft carrier can appear out of one horizon, run you down, and disappear into the other. Cross shipping lanes quickly, at right angles, and give them a wide berth before deploying sea anchors.

Deployment: Safety First

Offshore safety is many things, but first and foremost it is that conservative attitude of mind that never takes anything for granted. In particular, never take your sea anchor for granted. Take note that sea anchors are capable of pulling loads measured in tons. All lines must be properly flaked or coiled beforehand. Stand clear of coils when the rope is paying out.

If deployment is imminent always have the sea anchor in the water and properly set well before dark. Don't wait until the last minute! Monitor the forecasts and keep an eye on the barometer. A rapidly falling barometer means you are being overtaken by a huge atmospheric vacuum. Where there is a vacuum, air rushes in to stabilize the system. Rushing air means high winds and big waves. Pay attention to your barometer. Watch for wind clouds and learn to read the signs in the sea and sky. The Pardeys provide practical tips for doing so in Storm Tactics.

They also provide many useful tips about when to heave-to. Lin and Larry have made the equivalent of five circumnavigations and their advice is to heave-to early. Deploy the para-anchor early on in the game, before the bottom falls out of the barometer, before things get completely out of hand. Think about heaving-to before fatigue robs you of the ability to think clearly. The human mind is fragile and unless it can relax with some remission the force of its tension, it may snap and cease rendering good judgments. This is precisely why the Pardeys equate heaving-to with a safety valve.

Standing Set

The safest method of deploying a sea anchor is to allow the boat's drift to pay out the rode. The step by step scenario is as follows:

1. Head up into the wind, allow sails to luff and the boat to stall. Use the engine if you need to.

2. Lower/furl all sail.

3. Secure the rudder amidships.

4. Heave the float over board on the windward side and pay out the float line. The float line has been known to foul the parachute and its lines. Make certain it doesn't.

5. Slam dunk the sea anchor (or Deployment Bag) also on the WINDWARD side - never on the lee side, where the boat may drift over and foul.

6. As the boat drifts away from the para-anchor, snub the line early to help the chute open, and begin paying out the line/s. The float will be getting pulled into the water at this stage. DO NOT FULLY CLEAT THE LINE WITH ONLY A SHORT RODE OUT - give it half a turn on the cleat so you can slacken off quickly if necessary.

7. Secure the tether or bridle, apply chafing gear, go down below and take a coffee break.

The above method, called standing set, is the method that the authors recommend for heavy weather deployment. It is somewhat slow, and lines have a way of wanting to get under the boat initially (some sailors tie small fishing weights to the rode so that it will sink directly and not foul). But it is the safest method in heavy weather, especially for the novice. The alternative method, used by commercial fishermen and expert sailors is known as the flying set.

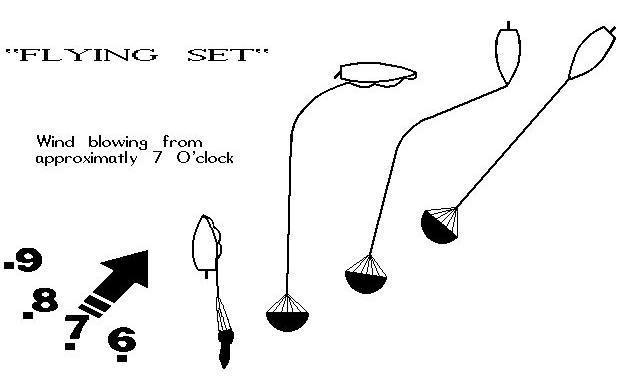

Flying Set

1. Bring the container of sea anchor and rode into the stern cockpit.

2. Take the bitter end of the rode, lead it outside all stays, rails, stanchions, etc., and secure it to the bow cleat (this can be done beforehand).

3. Furl all sail (do not attempt this maneuver with the mainsail up). Place engine in slow forward and steer a course with the wind at 7 o'clock.

4. Heave the float, and again, wait for the float line to pay out, then slam dunk the sea anchor off the stern quarter.

6. Keep moving the transmission in and out of slow forward, allowing the coils of rope to safely pay out behind the boat. (Expert sailors can use the storm jib instead of the engine).

7. With all but the last coils paid out, take the engine out of gear (or let the storm jib luff) and put the helm down - "RIGHT FULL RUDDER!" Wait for the wind to bring the bow around into the seas.

CAUTION: Because of the shock loads involved in attempting to stop a heavy boat that is moving downwind at some speed, Flying Set is not recommended in storm situations.

Although setting a large diameter parachute on the fly is quicker and much more positive, it is a tricky business, requiring much practice. Some sailors leave it too late, end up having to set the sea anchor on the fly, and it is usually a hair-raising experience.

If this is your last remaining option the author's advice is as follows: Carry out the maneuver with extreme effort! A half-hearted, sloppy effort just won't do here. Once you have decided to set the sea anchor on the fly you must act on that decision with single-minded resolve and determination.

Stay away from the coils of rope as they smoke out, and have a sharp knife ready just in case. Turning the boat around may be the most critical maneuver. One has to time the move precisely. Try to put the helm down behind a wave, in the trough area, where the rudder is most effective.

The Casanovas always set big parachutes on the fly. They practiced all the moves and could go through the motions instinctively. It is fast and efficient, but is a difficult and hazardous maneuver, especially in a pitch black night. It is far safer to deploy early on in the game, using the standing set.

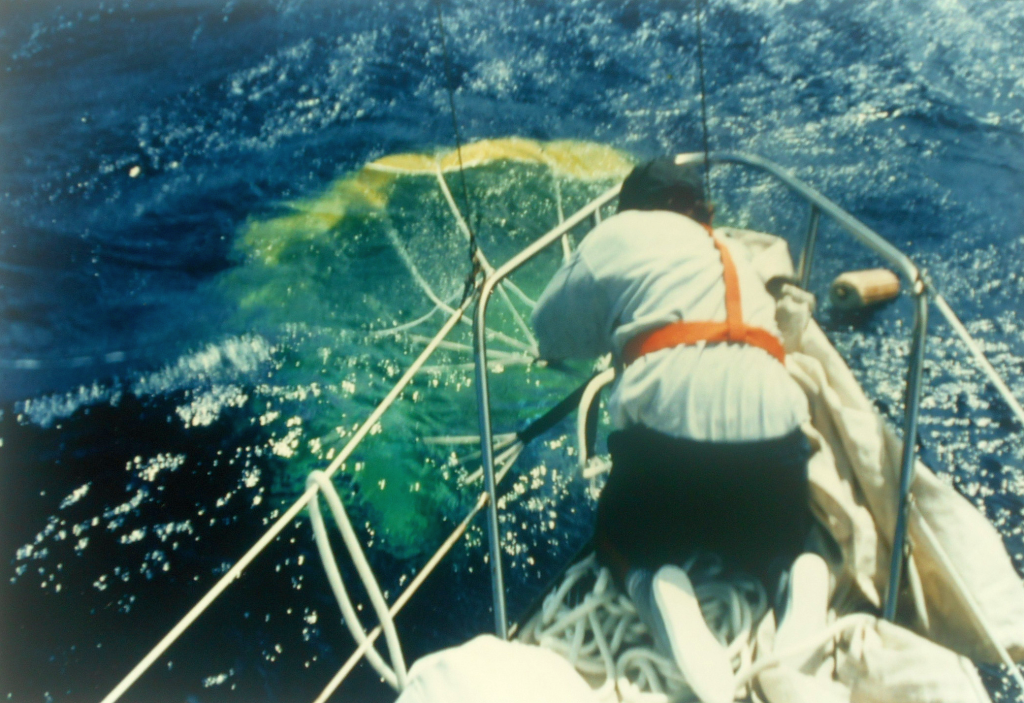

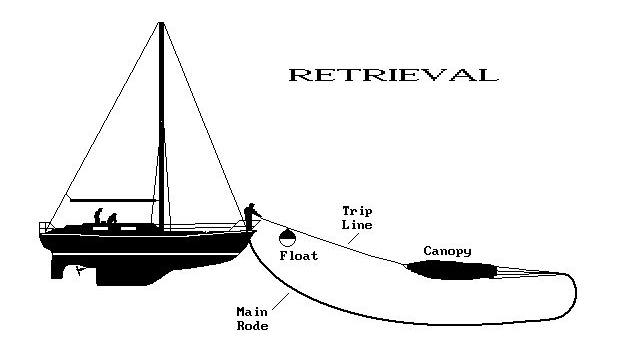

Retrieval

The largest para-anchor can be easily emptied out and retrieved by means of a tripping line connected to the center of the canopy (usually part of the package). Even so, allow plenty of time for retrieval, and try not to force anything. Remember, when retrieving a sea anchor one does not pull the sea anchor to the boat, rather the boat has to be pulled up to the sea anchor, even if that boat weighs ten tons.

Some sailors, among them the Pardeys, prefer not to use any tripping line or even float line at all - one less thing that might foul. In retrieving the sea anchor they wait until the seas calm down, then use a winch - or an engine - to bring the boat slowly up to it. When the parachute is within reach, they then grab hold of one or two shroud lines and pull, by so doing spilling the water out of the canopy. Once the canopy has been emptied it turns into a "limp rag" and can be brought on deck with relative ease.

This method of retrieval is fine, unless large swells are running, and that is when one can get into the divergence problems associated with orbital rotation - the problem the Monterey fisherman ran into.

Remember, as you are hauling the boat up to the sea anchor you will eventually arrive at the precarious juncture where the heavy boat is moving backward on a crest while the sea anchor is moving forward in the trough up ahead. As the two heavy objects diverge forces are brought to bear that can damage hardware or rip the sea anchor itself. You can avoid this potential hazard by the use of a tripping-line.